SANKEI INDUSTRIES and

SANKEI will move forward to a

new phase as SANKEI CORPORATION. Beyond "SANKEI Chairs"

SANKEI 's speedy and waste-free "Manufacturing System" that completes a series of manufacturing processes at a single location (Suzuka City, Mie Prefecture),

such as information gathering and analysis, product planning and proposal, development, design, production, quality control, sales, and distribution,

is the strength of SANKEI and the starting point for achieving reliable high quality, value pricing, and short delivery times.

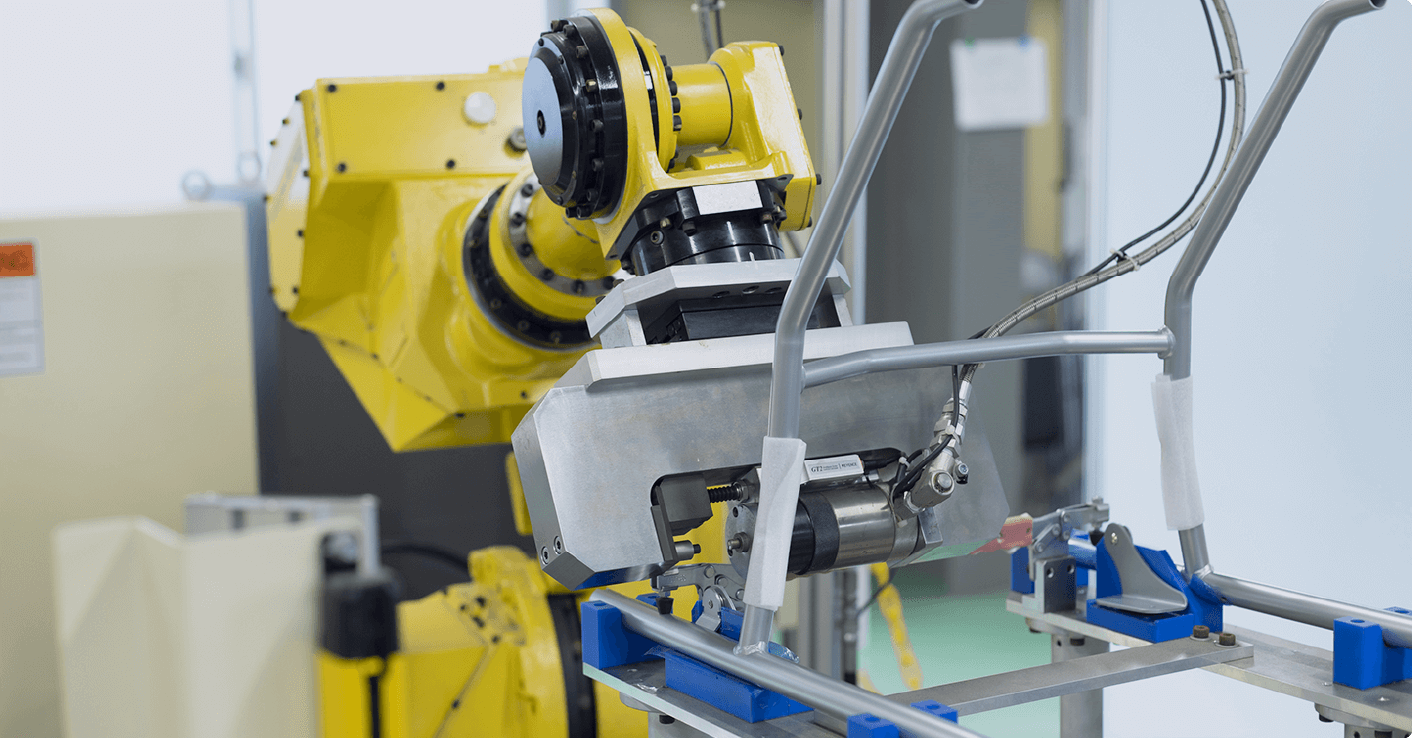

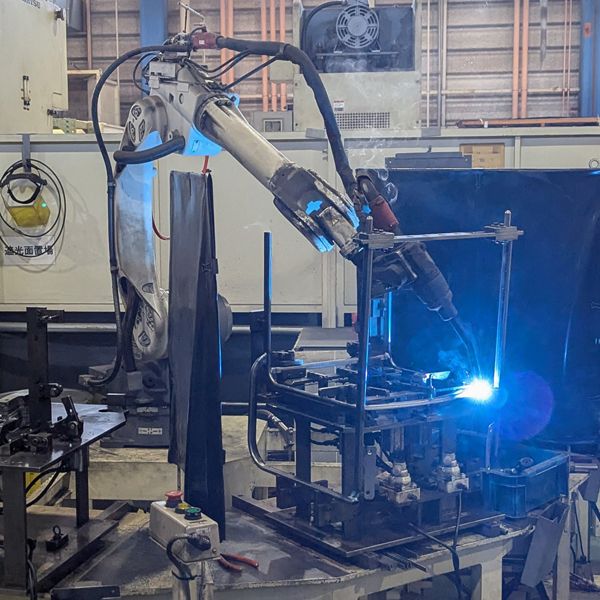

Rivet crimping work to join the pipe frame parts of chairs is automated by our own customized robot equipment. High productivity and quality can be realized.

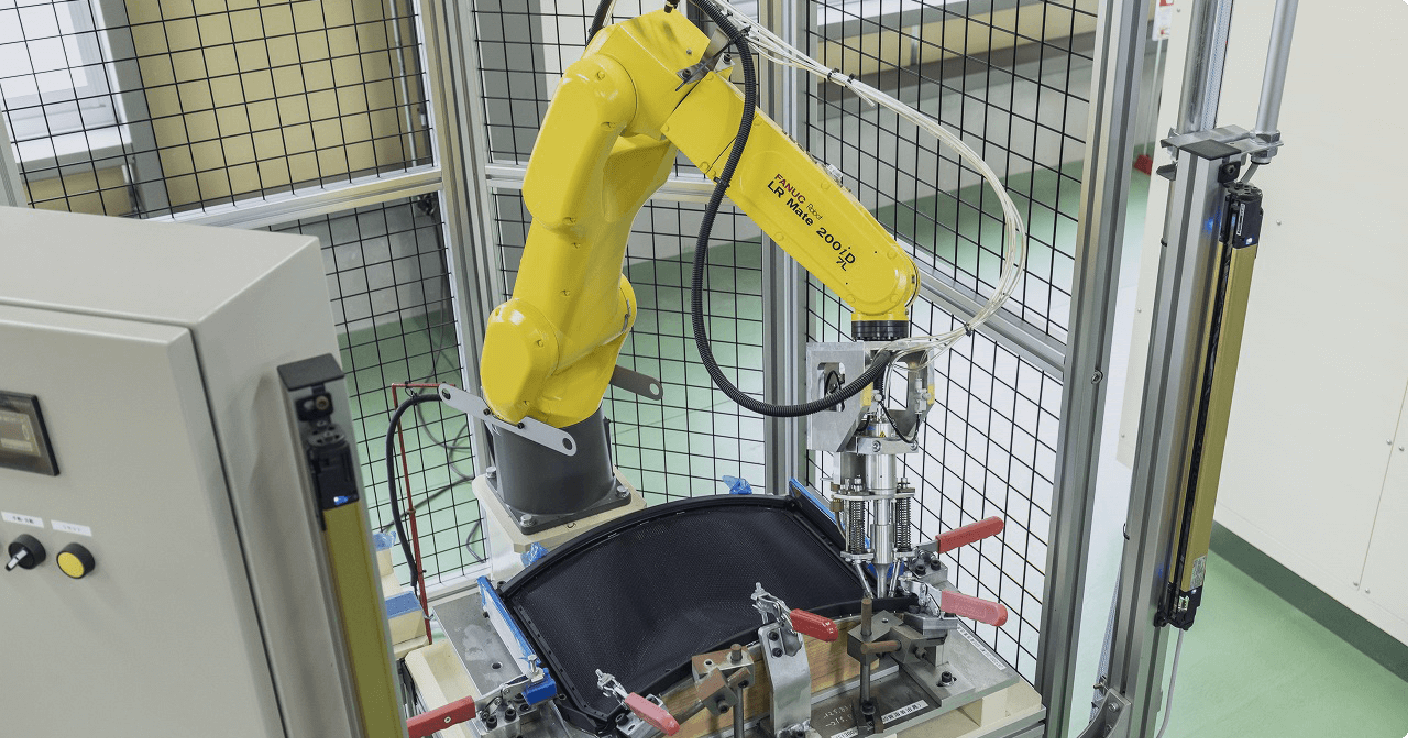

Ultrasonic welding melts and joins by frictional heating of the joining surfaces through ultrasonic vibration. We use this technology to automate the joining of plastic molded products and upholstery fabrics.

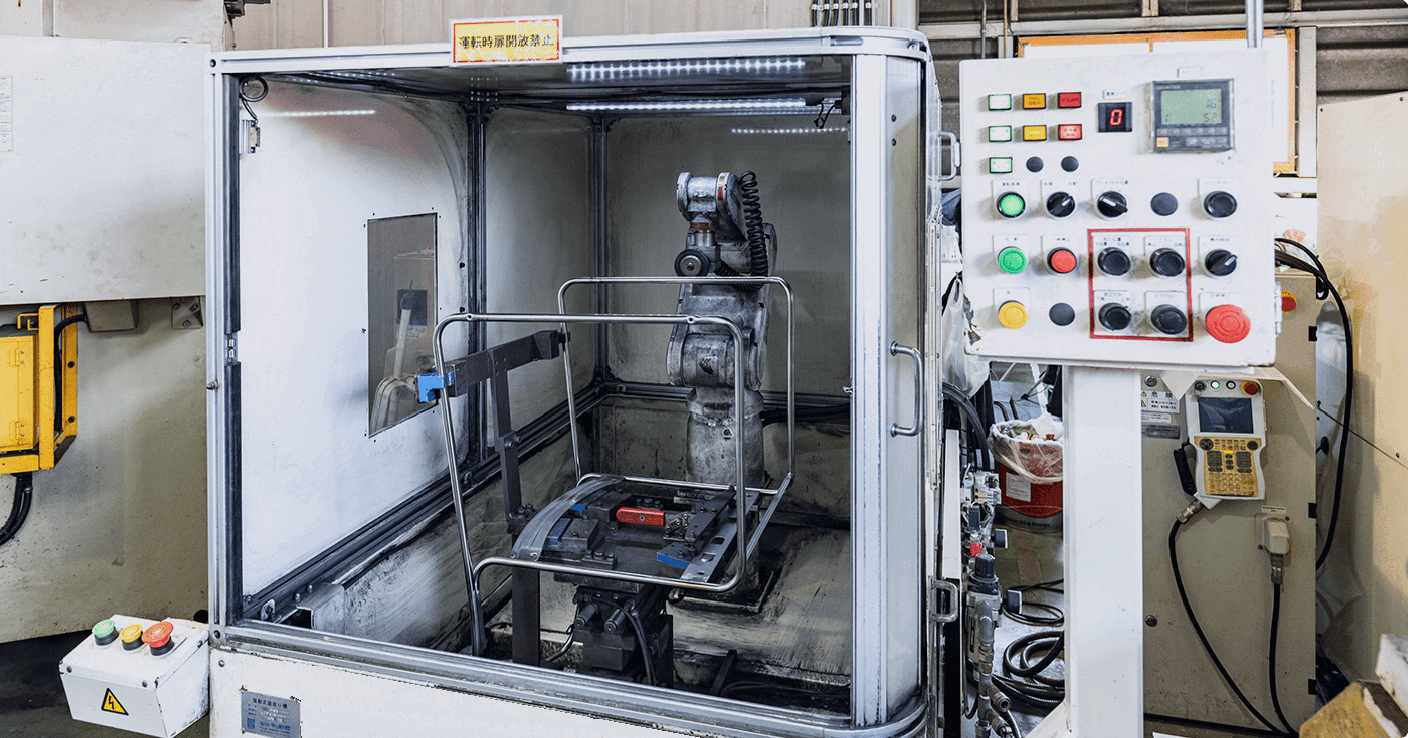

Scale produced in the welding process of stainless steel is polished off in a short time by a robot. Because no electrolytic solution is used, it is possible to perform this process in an environmentally friendly and safe way

A process to apply upholstery such as fabric to chairs by string binding without using a tacker. The upholstery, urethane, and core material can easily be disassembled by simply cutting with strings, contributing to global environmental protection.

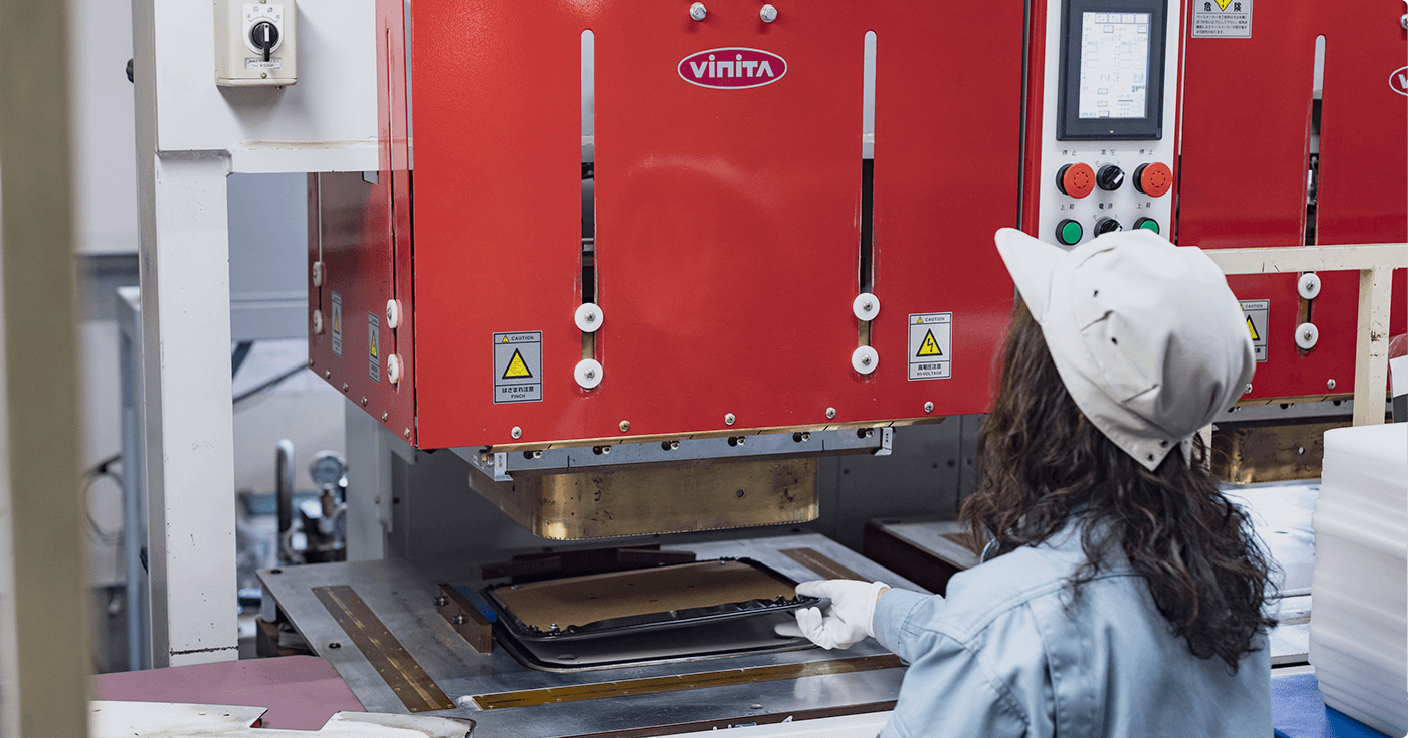

A process of welding upholstery using a specialized machine. It does not require craftsmanship and allows for mass production of products with stable quality.

An upholstery process using a tacker. This is a process that not only affects the exterior beauty of the product, but also the comfort of the seat, and requires skilled craftsmanship. We are committed to the tradition of these techniques.

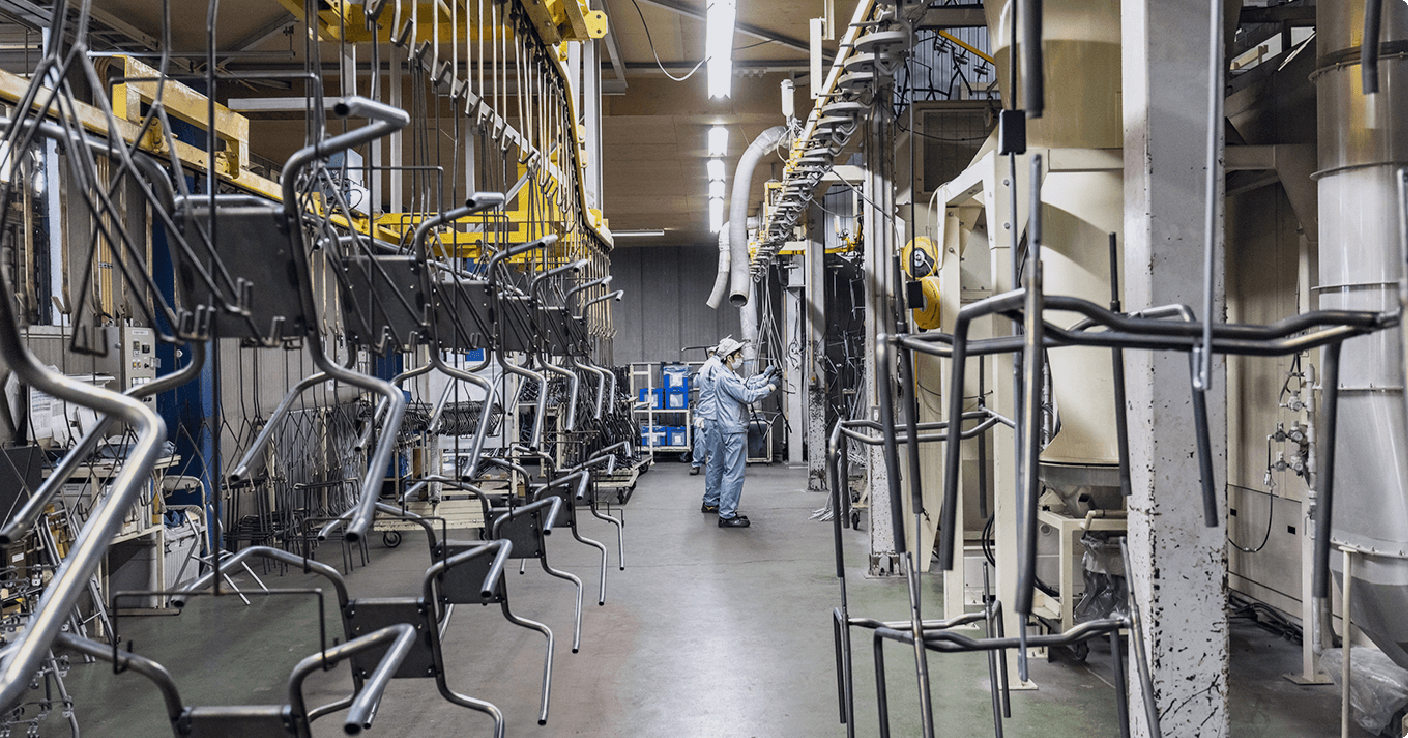

A coating method that uses static electricity to bond powdered paint and performs baking and drying at high temperatures. SANKEI has an automatic coating facility in its headquarters plant and is capable of mass production.

A new technology that can plasticize woody materials by press molding and form them into designs with a high degree of aesthetic appeal. We are conducting joint research with Kyoto University and others with the aim of practical application as a sustainable industrial material.

Using 3D CAD, we create CG visuals that are faithful to the image at the planning stage.

This leads to the creation of highly accurate prototypes that take into account factors such as design, functionality, and intended use.

| Company Name | SANKEI Corporation |

|---|---|

| Address |

|

| Representative | Representative Director President Atsunori Okada |

| Capital | 50,000,000 yen |

| Establishment | August 1951 |

| Affiliate Company |

|

We contribute to solving various issues in the world by utilizing our own technologies, centered on office furniture and beyond.

Product development of office furniture

We create original products with flexible ideas that break through common sense,

placing coexistence with the global environment at the center of our ideas.

Co-creative development

We are further pursuing our core technologies cultivated in chair manufacturing and working on co-creative development of

technologies and products that will be needed in the future.